Aquarium Chiller: A Complete Guide for Temperature Control

*We may earn a commission for purchases made using our links. Please see our disclosure to learn more.

In the challenging world of aquarium maintenance, temperature regulation often determines success or failure for hobbyists. While most aquarists understand the need for heaters in cold environments, cooling systems remain underutilized despite their critical importance. Aquarium chiller represents specialized equipment designed to combat temperature spikes that commonly occur from ambient heat, powerful lighting systems, or equipment operation.

For those keeping sensitive coral species, cold-water organisms, or maintaining breeding conditions for specialty species, a reliable chiller isn’t merely an accessory, it’s an essential investment for maintaining the delicate ecosystem within your glass walls.

Key Takeaways:

- Temperature stability is crucial for aquatic life, with even small fluctuations potentially causing stress or death

- Aquarium chillers are essential for tanks in warm climates, with high-powered lighting, or housing temperature-sensitive species

- Different chiller types (drop-in, inline, and thermoelectric) suit various tank sizes and needs

- Proper sizing is critical when selecting a chiller, based on tank volume, desired temperature drop, and ambient conditions

- Energy efficiency should be a primary consideration as chillers can significantly impact electricity bills

- Regular maintenance of chillers ensures optimal performance and longevity of the equipment

“Proper temperature control is perhaps the single most critical yet overlooked factor in aquarium keeping. For many species, particularly in reef environments, a temperature swing of just 2-3 degrees can mean the difference between thriving and perishing.”

– Dr. Ellen Prager, Marine Scientist and Author of “The Delicate Balance of Coral Reef Ecosystems”

Top Aquarium Chiller

1. JBJ Arctica Titanium Chiller – 1/10 HP

Keep your aquatic environment at the ideal temperature with the JBJ Aquarium Arctica Titanium Chiller. Designed with energy efficiency and quiet performance in mind, this 1/10 HP chiller is perfect for small to medium-sized tanks. Its corrosion-resistant titanium coil ensures long-lasting durability, while the environmentally safe R-134A refrigerant helps maintain a consistent water temperature without harming the ozone. With its sleek design and compact footprint, it's a top choice for aquarists looking to protect their aquatic life in style.

- Energy Efficiency: High-performance condenser uses less power, saving on energy costs.

- Quiet Operation: One of the quietest chillers available—ideal for home or office setups.

- Durability: Corrosion-resistant titanium and ozone-safe refrigerant ensure long-term reliability.

- Price Point: Higher upfront cost compared to other models in its class.

- Size Options Confusion: Listings and sizes may be inconsistent or unclear for some buyers.

- Bulky Design: Though compact, it may still require dedicated space due to its height.

This premium titanium aquarium chiller is renowned for its reliability and efficiency. The titanium heat exchanger prevents corrosion, making it suitable for both freshwater and saltwater applications. With a digital controller allowing precise temperature control within 1°F, this unit is perfect for medium-sized tanks up to 100 gallons. Its quiet operation makes it apartment-friendly, while the anti-leak design provides extra protection for your home.

The unit features a flow sensor that prevents operation when water flow is insufficient, protecting both your aquatic life and the equipment itself. JBJ’s reputation for quality control and customer service adds value beyond the hardware itself, with readily available replacement parts and technical support should issues arise.

2. Active Aqua Water Chiller Hydroponics System – 1/4 HP

The Active Aqua 1/4 HP Water Chiller is a versatile and efficient cooling solution for hydroponic systems, aquaponic reservoirs, aquariums, or even cold plunge baths. With its Boost function, it rapidly cools nutrient solutions and water, while the intuitive controls allow precise temperature management for optimal plant and aquatic life health. Engineered with a pure titanium anti-corrosive evaporator, it's built to withstand both freshwater and saltwater environments. With a cooling capacity of up to 92 gallons, this chiller is a reliable choice for serious growers and aquarists.

- Fast Cooling: Boost function provides rapid temperature drops for quick adjustments.

- Versatile Use: Suitable for hydroponics, aquaponics, aquariums, and cold plunge tubs.

- Durable Construction: Titanium evaporator resists corrosion in both fresh and saltwater setups.

- Pump Not Included: Requires additional purchase of compatible pump and hoses.

- Plastic Build: Less premium feel compared to metal-based models.

- Bulky Footprint: Large size may require significant space for setup.

The Active Aqua 1/4 HP Water Chiller delivers efficient and reliable cooling performance for a wide range of indoor applications. Designed to handle systems up to 92 gallons, it’s a favorite among hydroponic gardeners and aquarium hobbyists who need precise temperature control. The chiller features an intuitive digital interface and a convenient Boost function that rapidly brings temperatures down, making it ideal for demanding setups where quick cooling is essential.

Built with a pure titanium evaporator, this unit resists corrosion and supports both freshwater and saltwater environments. It maintains temperature stability within a tight ±0.5°F range, ensuring optimal conditions for plant health and aquatic life. Its quiet motor and smart compressor design minimize operational noise, while the energy-efficient refrigerant aligns with current eco-conscious standards. With durable construction and user-friendly operation, this chiller offers both power and peace of mind for indoor climate control.

3. IceProbe Thermoelectric Aquarium Chiller

The IceProbe Thermoelectric Aquarium Chiller by Nova is a compact, energy-efficient solution ideal for small aquariums, nano reefs, or desktop setups. Using thermoelectric technology, it quietly and effectively removes heat from your tank without the bulk of traditional chillers. Its simple design requires minimal installation—just mount the probe, plug it in, and let it maintain a stable temperature. With a durable build and included 1-year warranty, the IceProbe offers reliable performance for hobbyists who need precise cooling in tight spaces.

- Compact Size: Ideal for small tanks and tight spaces with minimal visual impact.

- Quiet Operation: Uses thermoelectric cooling with no compressor or loud fans.

- Energy Efficient: Low power consumption makes it budget- and eco-friendly.

- Limited Cooling Capacity: Best suited for small aquariums under 10 gallons.

- No Built-in Temperature Controller: Requires separate controller for automated regulation.

- Single-Tank Use: Not powerful enough for larger or multi-tank systems.

For nano tanks and small setups up to 20 gallons, the IceProbe offers an affordable and compact solution. Using thermoelectric technology instead of a compressor, it’s virtually silent and energy-efficient for small applications. This modular system allows flexibility in installation and can be adapted to various tank configurations, making it ideal for desktop aquariums or small specialty tanks.

The system operates through solid-state technology without refrigerants or moving parts beyond a small circulation fan, resulting in virtually maintenance-free operation. Its innovative design allows DIY integration into existing filtration systems or sumps. The IceProbe is particularly favored for sensitive biotopes like specialized shrimp tanks or for targeted cooling of specific areas within larger systems.

4. BAOSHISHAN Aquarium Water Chiller – 1/2 HP

The BAOSHISHAN 1/2 HP Chiller is a high-performance cooling solution designed for both large aquariums (up to 132 gallons) and home cold plunge setups. Its R290 eco-friendly refrigerant and freon-free compressor deliver fast, stable cooling without the need for constant refills or maintenance. Whether you're caring for axolotls, coral reefs, or exploring the benefits of cold therapy, this chiller provides precise temperature control down to 50°F for ice baths or 68–78°F for aquatic environments. The included setup accessories and one-year warranty ensure a hassle-free, reliable experience.

- Dual-Purpose Use: Compatible with both aquariums and cold plunge tubs for added versatility.

- Efficient Cooling: R290 refrigerant and freon-free compressor provide fast, stable, and eco-friendly temperature control.

- Easy Setup: Includes complete accessories for quick installation and use.

- Not Ideal for Small Tanks: Overpowered for aquariums under 50 gallons.

- Filter Required for Ice Baths: Needs an additional filter for optimal performance in cold plunge setups.

- Reduced Efficiency in Summer: Cooling performance may drop if water volume isn't reduced during hotter months.

This industrial-grade aquarium chiller is the workhorse option for serious aquarists with large systems or commercial applications. It can handle tanks up to 200 gallons and features a powerful compressor with environmentally friendly refrigerant. The unit includes advanced safety features like flow detection and temperature memory. While it commands a higher price tag, its durability and cooling power make it a worthy investment for serious hobbyists.

The BAOSHISHAN incorporates commercial-grade components including a titanium heat exchanger that resists corrosion even in aggressive marine environments. Its intelligent control system monitors multiple operational parameters simultaneously, providing automatic shutdown protection against power surges, water flow issues, or extreme temperature conditions. For large display tanks or multi-tank systems, its robust cooling capacity ensures stable temperatures even under challenging conditions.

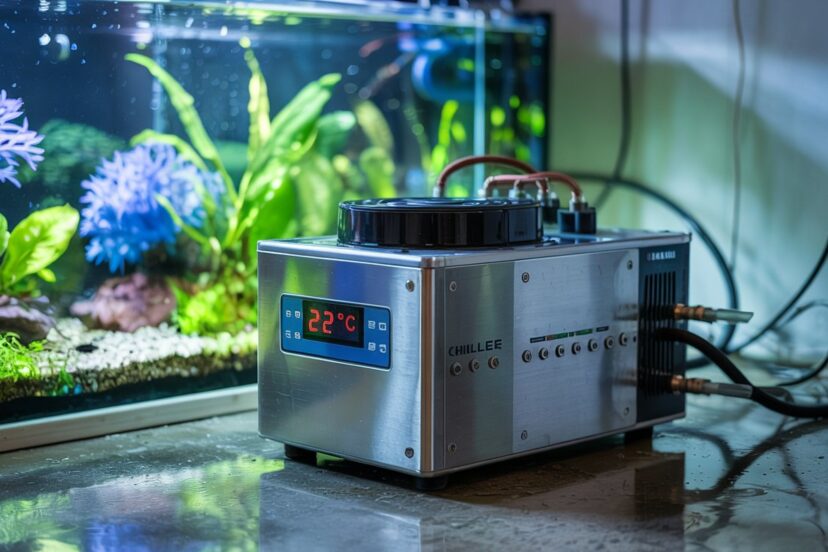

Understanding Aquarium Chillers: How They Work

Aquarium chillers operate on principles similar to refrigerators or air conditioners. Most models use a vapor compression cycle where refrigerant absorbs heat from the aquarium water and releases it outside the system. Water flows through the chiller’s heat exchanger, where it makes contact with cold surfaces connected to the refrigeration system. As the water passes through, its temperature drops before returning to the tank.

The refrigeration cycle involves four main stages:

- Compression: A compressor pressurizes the refrigerant gas, raising its temperature

- Condensation: The hot refrigerant travels through condenser coils where it releases heat and condenses into liquid form

- Expansion: The liquid refrigerant passes through an expansion valve, which reduces pressure and temperature

- Evaporation: The cold refrigerant absorbs heat from the aquarium water in the evaporator before returning to the compressor to repeat the cycle

The three primary types of aquarium chillers are:

1. Inline Chillers: These units connect directly to your filtration system’s output line. Water passes through the chiller before returning to the tank. They’re efficient and typically recommended for larger setups. Installation requires cutting into your plumbing line and securing the connections, often with specialized fittings or adapters. While more complex to install, they offer superior integration with existing filtration systems.

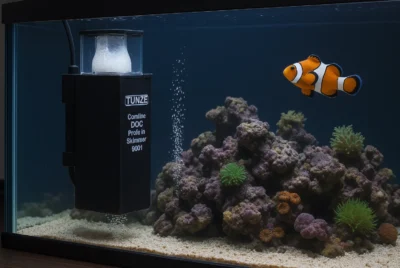

2. Drop-In Chillers: These units hang on the tank or sump and use a probe that sits directly in the water. They’re simpler to install but may be less efficient for larger systems. These chillers typically include a small pump that circulates water through the cooling unit before returning it to the tank. They’re ideal for beginners or those seeking easier installation, though they may be more visible in the display area.

3. Thermoelectric Chillers: Using the Peltier effect rather than compressors, these chillers are quieter but less powerful, making them suitable only for small tanks. They work by transferring heat between two electrical junctions when current passes through them. While limited in cooling capacity, they excel in situations requiring minimal temperature reduction or for spot-cooling specific areas within an aquarium.

Why You Might Need an Aquarium Chiller

Several scenarios might necessitate investing in an aquarium chiller:

High-powered lighting

Metal halide lights, intensive LED systems, and other high-output lighting can significantly raise water temperature, especially in smaller tanks. Modern reef lighting systems can produce substantial heat, with some high-end LED or T5 combinations generating as much heat as traditional metal halides. This effect is magnified in enclosed cabinets or smaller rooms with limited air circulation.

Warm climate locations

In tropical or hot regions, ambient room temperature may exceed the optimal range for many aquatic species, particularly during summer months. Even with air conditioning, maintaining consistent temperatures below 78°F (25.5°C) can be challenging in some climates. Seasonal temperature fluctuations can also create problems during heatwaves or when air conditioning systems fail.

Temperature-sensitive species

Certain fish, corals, and invertebrates require specific temperature ranges to thrive. Cold-water species like trout, certain goldfish varieties, and many North American native fish do better in cooler waters. Marine species like Acropora corals, anemones, and certain wrasses show stress symptoms when temperatures exceed their natural range for extended periods. Some specialized invertebrates like particular shrimp species or jellyfish have extremely narrow temperature tolerances that require precise cooling.

Breeding projects

Some fish species require temperature drops to trigger breeding behavior, making chillers essential tools for serious breeders. Species like discus, certain killifish, and many temperate species respond to temperature manipulation as part of their reproductive cycle. Being able to precisely control temperature drops and gradual increases can significantly improve breeding success rates.

Disease treatment

Certain parasites and bacteria thrive in warmer waters, and temporarily lowering tank temperature can help combat these issues in conjunction with other treatments. Ich (Ichthyophthirius multifiliis) and certain bacterial infections proliferate more slowly at lower temperatures, giving fish immune systems more opportunity to respond effectively. Temperature management becomes a critical aspect of quarantine protocols for many advanced aquarists.

Equipment heat contribution

Pumps, filters, UV sterilizers, and other equipment transfer heat to water through friction and motor operation. In heavily equipped systems, this cumulative effect can raise temperatures by several degrees, particularly in enclosed cabinet setups with limited ventilation. High-flow systems with powerful return pumps are particularly susceptible to this issue.

Choosing the Right Chiller for Your Aquarium

Selecting an appropriate aquarium chiller involves considering several factors:

- Tank Size: Chiller capacity, measured in horsepower (HP), should match your tank volume.

- 1/10 HP: For tanks up to 50-75 gallons

- 1/4 HP: For 75-150 gallon systems

- 1/2 HP: For 150-250 gallon aquariums

- Larger tanks may need multiple units or commercial-grade equipment.

- Temperature Differential: The difference between your desired temperature and ambient conditions affects chiller sizing. If you need to maintain a tank at 72°F in a room that reaches 85°F, you’ll need significantly more cooling power than for a smaller temperature gap. As a rule of thumb, add 1/10 HP for every 5°F of additional cooling required beyond standard conditions.

- Water Flow Rate: Chillers require adequate water flow to function efficiently. Manufacturers specify minimum and maximum flow rates for each model. Insufficient flow reduces cooling efficiency, while excessive flow prevents proper heat exchange. Match your pump’s output to the chiller’s recommended flow rate, potentially adding a dedicated pump if necessary.

- Energy Efficiency: Modern chillers offer varying levels of energy efficiency. Look for models with higher Coefficient of Performance (COP) ratings and energy-saving features like programmable timers or variable-speed compressors. While more efficient models typically cost more initially, they can save substantial amounts over their operational lifetime.

- Noise Level: Compressor-based chillers generate noise during operation. If your aquarium is in a living space or bedroom, prioritize models with noise-reduction features like insulated compressor compartments or vibration-dampening feet. Thermoelectric models offer near-silent operation but with limited cooling capacity.

- Installation Requirements: Consider the physical space available for your chiller. Units need adequate ventilation around their condenser coils and should be protected from water splashes or high humidity. Some models require specific plumbing configurations or electrical connections that may necessitate professional installation.

Installation Best Practices

Proper installation significantly impacts an aquarium chiller’s performance and longevity:

- Location: Place the chiller in a well-ventilated area with at least 12 inches of clearance around air intake and exhaust vents. Never place chillers in enclosed cabinets without proper ventilation, as the expelled heat must dissipate efficiently. Avoid locations with direct sunlight or high ambient temperatures, which reduce cooling efficiency.

- Plumbing: Use appropriate pipe diameter to match your chiller’s inlet/outlet ports. Install unions or quick-disconnect fittings to facilitate maintenance. Consider adding ball valves before and after the chiller to allow isolation during service without draining the system. Use thread tape on threaded connections to prevent leaks, and secure all hose connections with hose clamps.

- Flow Control: Install a flow meter to ensure optimal water circulation through the chiller. Some advanced setups benefit from controllable DC pumps that can adjust flow rates precisely. If your main system pump provides excessive flow, consider adding a bypass valve to divert excess water around the chiller while maintaining optimal flow through the cooling chamber.

- Electrical Considerations: Connect chillers to GFCI-protected outlets positioned away from potential water splashes. Consider dedicated circuits for larger models to prevent overloading household circuits. Use drip loops on all power cords to prevent water from following cables to electrical connections.

- Temperature Probes: Position the chiller’s temperature sensor in a location with good water flow that represents the average tank temperature. Avoid placing it near heaters, return nozzles, or in dead zones with limited circulation. Some advanced setups benefit from secondary temperature monitoring systems to verify the chiller’s sensor accuracy.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and extends equipment lifespan:

- Condenser Cleaning: Clean the air-cooled condenser coils monthly using compressed air or a soft brush to remove dust and debris. For models with washable air filters, rinse according to manufacturer guidelines, typically every 2-4 weeks in dusty environments.

- Water Filter Installation: Install a mechanical filter before the chiller’s water intake to prevent debris from clogging the heat exchanger. Fine particulate matter, especially in reef systems with sand substrates, can gradually reduce cooling efficiency by coating internal surfaces.

- Regular Inspections: Check all plumbing connections monthly for signs of leaks or deterioration. Inspect electrical connections for corrosion, particularly in salt environments. Monitor normal operating sounds and temperatures to identify potential issues early.

- Performance Monitoring: Log your chiller’s duty cycle and cooling efficiency seasonally. Increased runtime or reduced cooling capacity often indicates developing problems like refrigerant leaks or scale buildup in the heat exchanger. Most problems are less expensive to address when caught early.

Common issues and solutions include:

- Insufficient Cooling: Check water flow rate, clean condenser coils, verify that ambient temperature is within the unit’s specifications, and ensure adequate ventilation around the unit. In extreme conditions, adding shade or auxiliary room cooling may be necessary.

- Excessive Cycling: Adjust the temperature differential setting if available. The ideal setting prevents the chiller from rapidly turning on and off, which stresses the compressor and reduces lifespan. Most units perform best with 1-2°F differential settings.

- Unusual Noises: Rattling might indicate loose components, while grinding or squealing often suggests compressor problems. Immediately disconnect power and consult a technician if abnormal sounds develop. Remember that many warranties become void if unauthorized repairs are attempted.

- Ice Formation: Ice on refrigerant lines typically indicates airflow problems or refrigerant issues requiring professional service. Never operate a chiller with visible ice formation, as this can damage the compressor.

Energy Efficiency Considerations

Chillers can significantly impact electricity bills, making efficiency crucial:

- Insulation: Insulate tanks and sumps using foam panels on sides and bottom not visible to viewers. Cover open sump areas with acrylic lids to reduce evaporative heat exchange and minimize humidity in the stand.

- Ambient Temperature Control: Each degree you can lower room temperature through air conditioning or improved ventilation directly reduces chiller workload. In some cases, a small room air conditioner operates more efficiently than an aquarium chiller.

- Lighting Schedule: Program lights to operate during cooler nighttime hours when possible, particularly high-heat systems like metal halides. Consider splitting photoperiods with a midday dimming period to reduce heat accumulation.

- Chiller Timing: Use controllers that enable the chiller to run primarily during off-peak electricity hours. Some advanced aquarium controllers allow programming around time-of-use electricity rates.

- Heat Recovery Systems: In cold climates, direct chiller exhaust heat into room space during winter months. Advanced setups can incorporate heat exchangers to capture waste heat for other purposes, such as heating water for water changes.

Conclusion

Aquarium chillers represent a significant but potentially essential investment for serious aquarists. When selected appropriately, installed correctly, and maintained regularly, they provide the temperature stability critical for sensitive species and challenging aquatic environments. Beyond merely keeping water cool, modern chillers offer precise temperature control that enables successful keeping of species once considered too demanding for home aquariums.

While the initial cost and ongoing electricity consumption require consideration, the protection they provide for valuable livestock and the expanded possibilities they create for specialized biotopes justify the investment for many enthusiasts. By understanding the principles behind chiller operation, carefully matching equipment to your specific needs, and implementing energy-efficient practices, you can create optimal conditions for even the most demanding aquatic species.

Frequently Asked Questions

Can I use fans instead of a chiller for my aquarium?

Surface fans can reduce water temperature through evaporative cooling, typically achieving 2-4°F drops in moderate humidity environments. They’re most effective for small to medium tanks requiring minimal cooling or as supplementary cooling in conjunction with chillers during peak summer periods. However, fans increase evaporation rates substantially, requiring more frequent top-offs and potentially affecting water chemistry in sensitive systems. For serious cooling needs or precise temperature control, proper chillers remain the only reliable solution.

How loud are aquarium chillers?

Noise levels vary significantly between models and technologies. Compressor-based chillers typically produce 45-60 decibels (similar to conversation or background office noise), with higher-end models featuring sound insulation at the lower end of this range. Thermoelectric models generate minimal compressor noise but still require fans that produce 35-45 decibels. Room placement, maintenance condition, and vibration isolation all affect perceived noise. Most users find modern chillers acceptable in living spaces when properly installed with anti-vibration pads.

How much will a chiller increase my electricity bill?

Energy consumption depends on chiller size, efficiency, runtime, and local electricity costs. A typical 1/10 HP unit draws 200-300 watts while running and might operate 6-12 hours daily during warm seasons, resulting in 36-108 kWh monthly consumption. At $0.15/kWh, this translates to approximately $5-$16 added to monthly electricity bills. Larger units consume proportionately more power, while modern energy-efficient models featuring digital inverter technology can reduce consumption by 20-30% compared to older designs.

Can I use the same chiller for freshwater and saltwater aquariums?

Models with titanium heat exchangers are compatible with both freshwater and marine applications, as titanium resists corrosion from salt, medications, and pH fluctuations. However, switching a unit between system types requires thorough cleaning of all water-contact surfaces. Some manufacturers recommend dedicated chillers for each water type to prevent cross-contamination of beneficial bacteria or potential disease transmission. Always verify materials compatibility if considering a transfer between system types, as some budget models use copper components unsuitable for reef applications.

How do I know what size chiller I need?

Properly sizing a chiller involves calculating the total heat load from lighting, pumps, ambient temperature, and other equipment. As a starting guideline, multiple your tank volume in gallons by 4 (for edge cases) to determine minimum BTU/hr requirements, then select a chiller offering 15-20% additional capacity for adequate headroom. For precise sizing, use manufacturer-provided calculators that incorporate your specific parameters including desired temperature, ambient conditions, tank insulation, and equipment heat load. Undersized chillers lead to excessive runtime and premature failure, while oversized units cost more and may cycle too frequently.